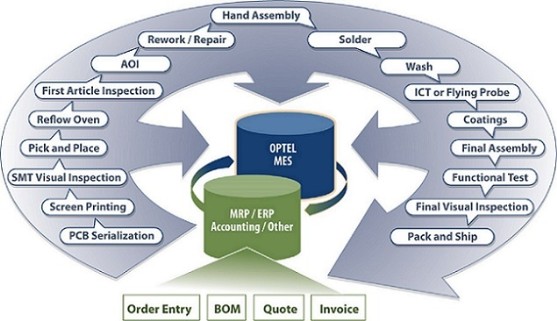

Optel tracks, controls, collects process parameters, and enforces routing operations per serial number, which allows manufacturers to ensure process compliance. Three levels of enforcement are available for configuration, depending on the specific need for production process control. Electronic work order job travelers are available online, in real time, which eliminates the potential loss or misplacement of paper job travelers and provides a permanent record for customer proof-of-process requests. In compliance with IPC-1782 Traceability standard, Optel collects the following common process traceability data for every operation: operation name and ID, date and time in/out, cycle time, operation documentation ID, program/setup data (name/revision/date), significant downtime, date of last preventive maintenance, start time and duration for in-process exception/maintenance/adjustment, environment (temperature and humidity).